%

%

%

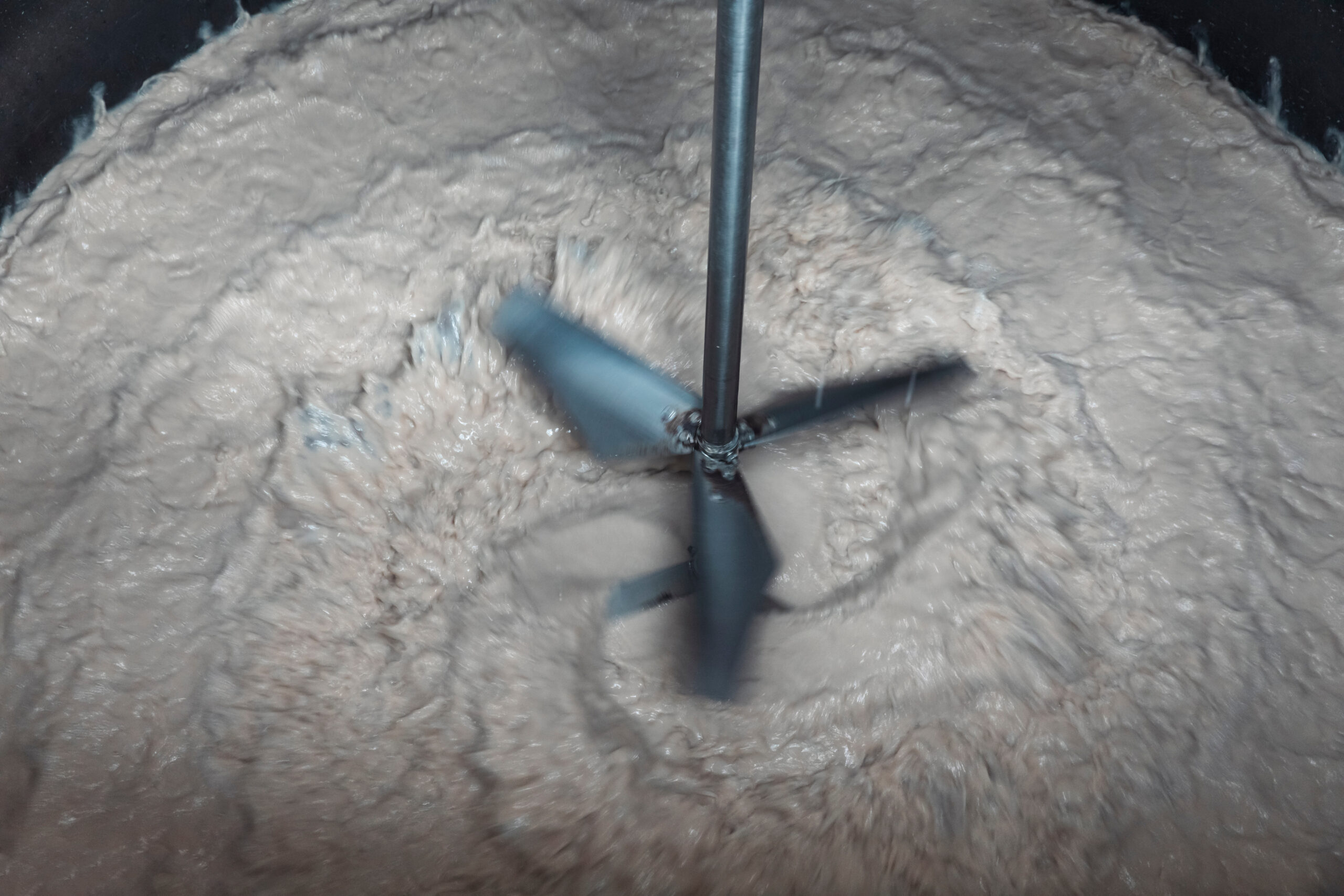

Na Grestel comprometemo-nos em tornar o grés ainda mais sustentável. Nesse sentido, estabelecemos uma parceria com a Universidade de Aveiro (Portugal) de forma a desenvolver uma nova matéria-prima, reciclando e reutilizando argilas e esmaltes das nossas próprias operações, assim como outros resíduos de indústrias próximas. O resultado é Ecogres® (ecogres), uma argila reinventada a partir materiais reciclados.

Os nossos designers desempenham um papel fundamental na implementação da sustentabilidade na produção de grés. Minimizar o impacto ambiental dos nossos produtos passa por considerar a forma, a ergonomia, a estética e a durabilidade, enquanto otimizamos o uso de recursos como argila, vidrado, energia e água. Todos os produtos são concebidos para serem ecológicos, reutilizáveis e recicláveis, com desperdício mínimo durante a produção.

As nossas embalagens são 100% livres de plástico e recicláveis, utilizando apenas corantes não perigosos. Para reduzir desperdícios, desenvolvemos o Ecocard, feito a partir de resíduos de cartão interno triturado, utilizado em 15% das nossas caixas. As nossas caixas são certificadas FSC (75% de cartão reciclado), seladas com fita de papel reciclado e concebidas para serem reutilizáveis.

Comprometemo-nos a manter elevados padrões éticos nas nossas operações comerciais, garantindo o cumprimento de todas as leis e regulamentos de acordo com os padrões da UE. Auditorias regulares, realizadas por entidades oficiais e auditores independentes, verificam o cumprimento destes padrões.

Priorizamos a eficiência energética aproveitando 1180 kW de energia solar, permitindo que a nossa fábrica mais recente funcione totalmente com energia própria durante o dia. As restantes fábricas operam com uma combinação de energia solar e outras fontes renováveis. Os nossos fornos são 15% mais eficientes do que os mais eficientes do mercado, graças ao nosso inovador sistema de circuito fechado que reutiliza o calor. Além disso, o nosso processo de queima única minimiza ainda mais o consumo de energia e as emissões de CO₂, e estamos na vanguarda na Europa ao testar a queima industrial de cerâmica utilitária com energia a hidrogénio.

Todos os resíduos que geramos são cuidadosamente geridos. 99% do nosso desperdício é reciclado ou reutilizado no nosso processo de produção. 99% dos nossos resíduos são enviados para processos de reciclagem ou valorização, transformando-se em subprodutos incorporados noutras indústrias. Com o Ecogres®, criámos uma nova matéria-prima a partir de argilas e vidrados reciclados, bem como de resíduos de indústrias próximas.

Para além das nossas práticas de redução do consumo, 100% da água é cuidadosamente tratada e reutilizada em processos internos de limpeza ou reintroduzida no nosso processo de produção.

Cada uma das nossas fábricas está equipada com uma estação industrial de tratamento de águas residuais (ETARI), em conformidade com os padrões da UE. Reciclamos toda a argila excedente das nossas fábricas em peças novas, limitando assim as emissões associadas ao transporte.